.

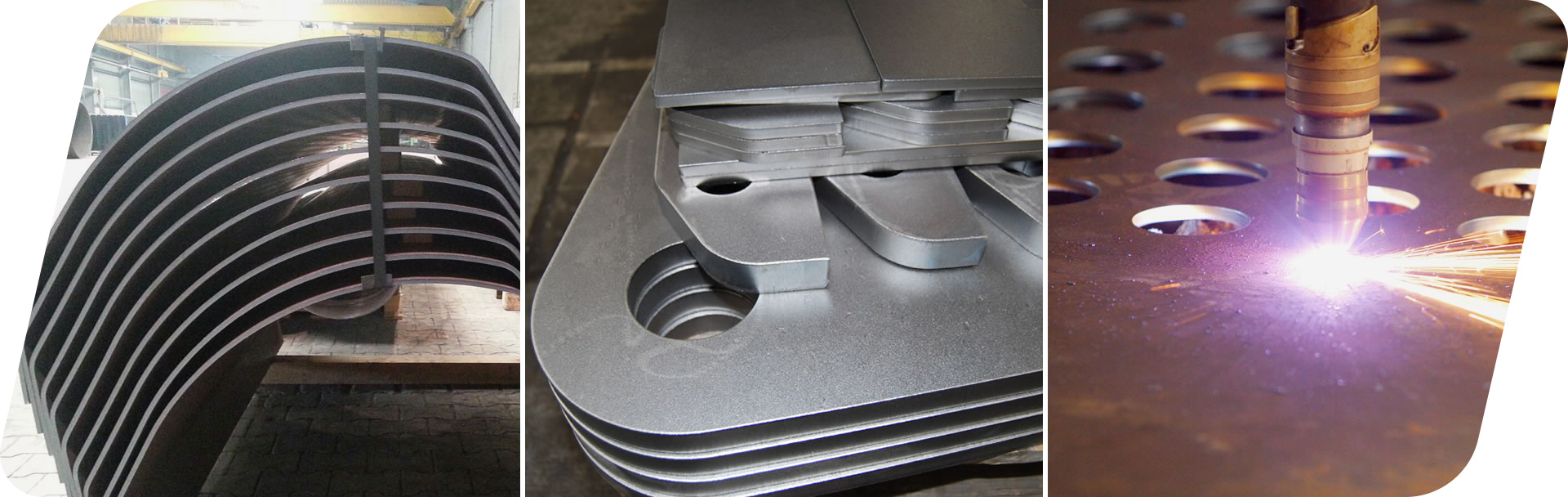

Cut shapes

The production of such flame-cut parts takes place within the framework of customer specifications, which are supplied in the form of drawings or sketches. The production process is usually carried out using computer-controlled cutting systems. Various techniques are used to cut the material according to the specifications.

Oxyfuel flame cutting

Autogenous flame cutting or oxyfuel cutting is one of the best-known manufacturing processes for flame-cut steel parts. Mild steel and low-alloy steels are cut by oxy-fuel flame cutting. However, this does not apply to aluminum or stainless steel. Metals that have a lower melting point than the base metal are required.

In the oxy-fuel cutting process, a flame heats the material and the oxygen supplied burns it. The underlying layers are also heated to ignition temperature by the resulting combustion heat. Because the process continues automatically into the deeper layers, only the surface of the material needs to be heated. The self-perpetuating process is referred to as an autogenous process. The ignition temperature must be below the melting temperature of the material.

During cutting, slag is produced which is blown out by the cutting oxygen jet. This can generate pressures of up to 20 bar. The task of the oxygen jet is not only to provide the oxygen for combustion, but also to blow out the slag.

Oxyfuel cutting systems

- Table sizes 6 x 30 m and 12 x 20 m

- Material thicknesses 10 – 300 mm

- Flame cutting systems with up to 12 machine torches

- Unit weight (starting material) maximum 28 t

- CNC-controlled torch carriage positioning

- Suitable for mirror-image cutting (e.g. for gear racks)

Oxyfuel cutting system for thick sheets

- (150-600 mm)

- Table size 4 x 8 m

- Unit weight (starting material) maximum 45 t

Strip burning system with 32 machine torches

- Material thicknesses: 8-60 mm, on request from 4 and up to 100 mm possible

- Smallest possible thickness/width combination: 40 x 6 mm and square from 40 x 40 mm, other combinations possible on request

- Lengths up to 12,000 mm

- Lowest possible deviation in straightness, i.e. little twisting or saberiness

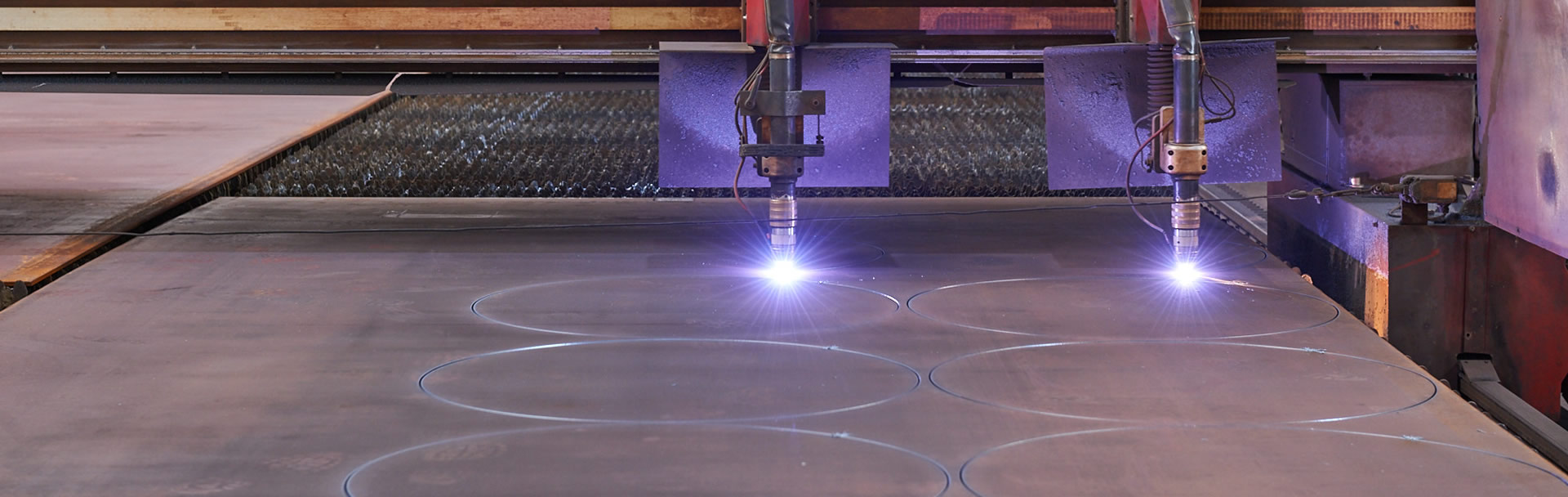

Plasma cutting

Plasma cutting is another method of producing flame-cut parts. It is primarily suitable for materials made of steel, aluminum, copper and brass as well as conductive metals.

It uses a hot jet to cut through workpieces made of electrically conductive materials. The jet also separates thick sheets efficiently. Plasma cutting creates an electrical channel of ionized gas through the workpiece. A closed circuit to the plasma cutter is formed via an earthing terminal. The electrically conductive plasma channel generates sufficient heat to melt the workpiece. The high-speed plasma and pressurized gas then blow away the molten metal and cut the workpiece.

Plasma cutting systems are versatile because they are able to cut multi-dimensionally with multiple axes.

CNC-controlled plasma cutting systems

- Table size 5 x 28 m

- Material thicknesses 4 – 25 mm

- Cutting systems with up to 2 machine torches

- Signing for the preparation of welded constructions or for forming

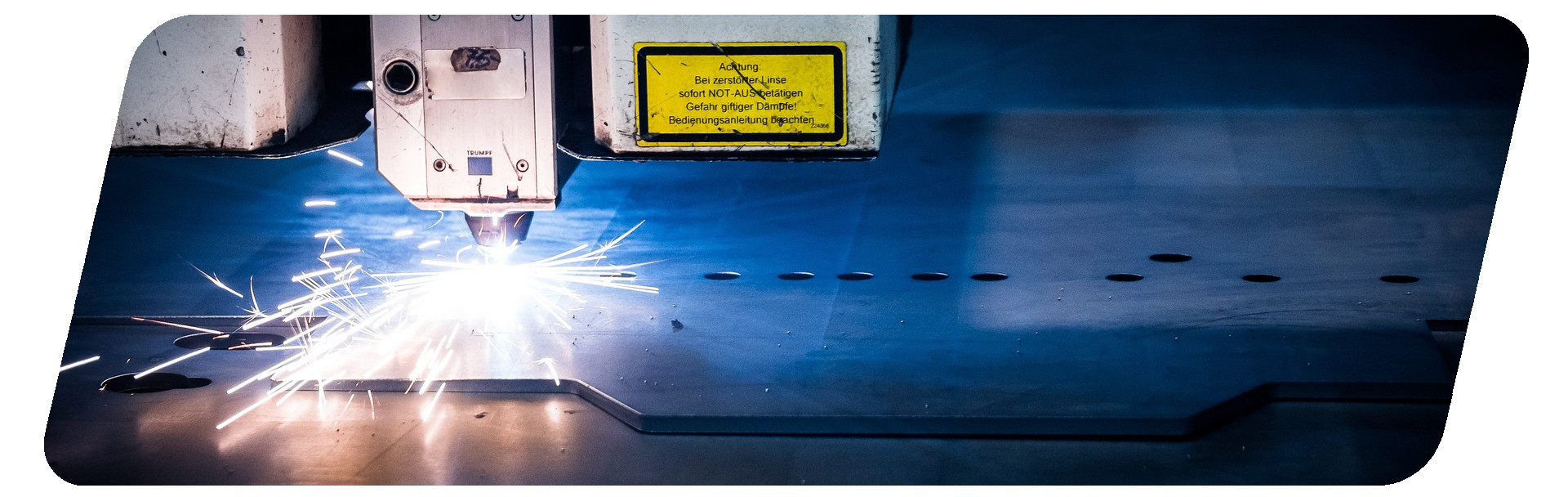

Laser cutting

Flame-cut parts can be produced using laser cutting. In laser cutting, the laser beam separates a solid body by means of so-called material ablation. The cutting process can be used to cut metallic and non-metallic materials. A guided, shaped and bundled laser beam hits a workpiece and heats it intensely. The power of the laser is concentrated on a point with a diameter of around half a millimeter or less. As soon as more heat is generated at this point than is dissipated by heat conduction, the workpiece is cut – the material is completely penetrated.

The advantage of this method is the low material wear. This is due to the non-contact work of the laser beam, which neither deforms nor damages the workpiece. The results are characterized by low edge roughness and burr formation, which – depending on the sheet thickness – means that hardly any post-processing is necessary.

Laser cutting is an innovative manufacturing process that is constantly evolving. The technology can be used to cut in two and three dimensions with multiple axes.

Advantages of laser cutting

- Laser systems up to 12 kW

- Table sizes up to 3.5 x 14 m

- Material thicknesses of up to 25 mm (depending on the material quality)

- Small heat-affected zone

- No to minimal distortion due to heat

- smallest tolerances possible (+/-0.1 mm)

Minimum angular deviation (max. 0.3 mm), tighter tolerances on request. Little to no reworking of the cutting contours.

Materials

The parts can be made of steel, stainless steel, aluminum or copper. Plasma cutting is generally used for thicknesses between three and 50 millimetres. It is considered the best manufacturing solution for steel, titanium or copper alloys. Plate thicknesses between 50 and 300 millimetres are efficiently processed using flame cutting.

The laser cuts through steel, aluminum and stainless steel with sheet thicknesses between 0.5 and 30 millimeters. Laser cutting is also suitable for non-metallic materials such as plastics, glass or wood.

In order to optimize the cost-effectiveness of flame cutting technology, a combination of different techniques can be useful.

Industries

Flame-cut parts are primarily required in mechanical and special machine construction, vehicle construction and metal construction. Companies that manufacture construction machinery also use these parts made of steel or other materials as the basis for the manufacture of their products. As individual pieces or series flame-cut parts, they are used as struts for steel girders or shaped blanks for steel construction. Stainless steel flame-cut parts are used in the field of interior design, for example. These include individual stair railings, balcony railings or steel furniture.

Order flame-cut parts online

UnionStahl Nord GmbH stands for high-quality flame-cut parts made of steel and stainless steel. We are characterized by our expertise and many years of experience. If you would like to order flame-cut parts online, we will be happy to advise you on your individual requirements.

Our cutting systems are state of the art. Our competent employees guarantee you above-average quality with reliable delivery times.

FAQ

What do cut shapes cost?

The price of cut shapes always depends very much on the quantity, the desired delivery time and the material. We will be happy to make you an individual offer on request.

What is the current delivery time?

Despite the current crisis, we can offer fast and reliable delivery times. We will be happy to provide you with specific delivery times on request.

Which cut shapes do I need?

If you are not yet sure exactly which focal parts you need for your project, we will be happy to advise you free of charge and without obligation. Thanks to our many years of experience in this field, we know exactly what suits you best. Your personal contact.