S355J2+N: High-Quality Structural Steel with Optimal Properties

S355J2+N is an unalloyed structural steel suitable for various applications with different solutions. The designation “S355” refers to a minimum yield strength of 355 MPa, while “J2” indicates a notch impact toughness of 27 joules at -20°C. The “+N” signifies that the steel has been normalized, resulting in improved mechanical properties.

Chemical Composition of S355J2+N

S355J2+N consists of an optimal blend of carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), chromium (Cr), nickel (Ni), and copper (Cu), giving it high strength and toughness.

Mechanical Properties

- Yield Strength: approx. ≥ 355 MPa (depending on material thickness)

- Tensile Strength: 470 – 630 MPa (depending on material thickness)

- Impact Toughness: ≥ 27 J at -20°C and -40°C

- Weldability (CEV %): approx. 0.45 (depending on material thickness)

- Density: 8.00 g/cm³ (standard density for structural steels)

Advantages of S355J2+N Compared to Other Steel Grades

- Very good dimensional stability

- Higher load-bearing capacity and toughness

- Good weldability and machinability

- Improved ductility through normalization

- Good machinability

Manufacturing Process of S355J2+N

The manufacturing process of S355J2+N typically begins with the extraction and melting of raw materials such as iron ore, coke, and various alloying elements. A crucial step in the production is the normalization (“+N”), which gives the S355J2+N its optimized microstructure. In this process, the billet is heated to 850–950°C, held for a defined period, and then slowly air-cooled. This reduces internal stresses, improves the grain structure, and ensures a uniform distribution of the microstructure.

Quality control is carried out through mechanical tests such as tensile tests, impact bending tests, and ultrasonic inspections.

Additionally, S355J2+N must meet the requirements of DIN EN 10025-2 and is certified with a 3.1 or 3.2 certificate.

Influence of Normalization on the Material Properties

Through normalization, the grain structure of the steel is improved, resulting in a more uniform microstructure and, therefore, greater homogeneity of the steel.

Applications

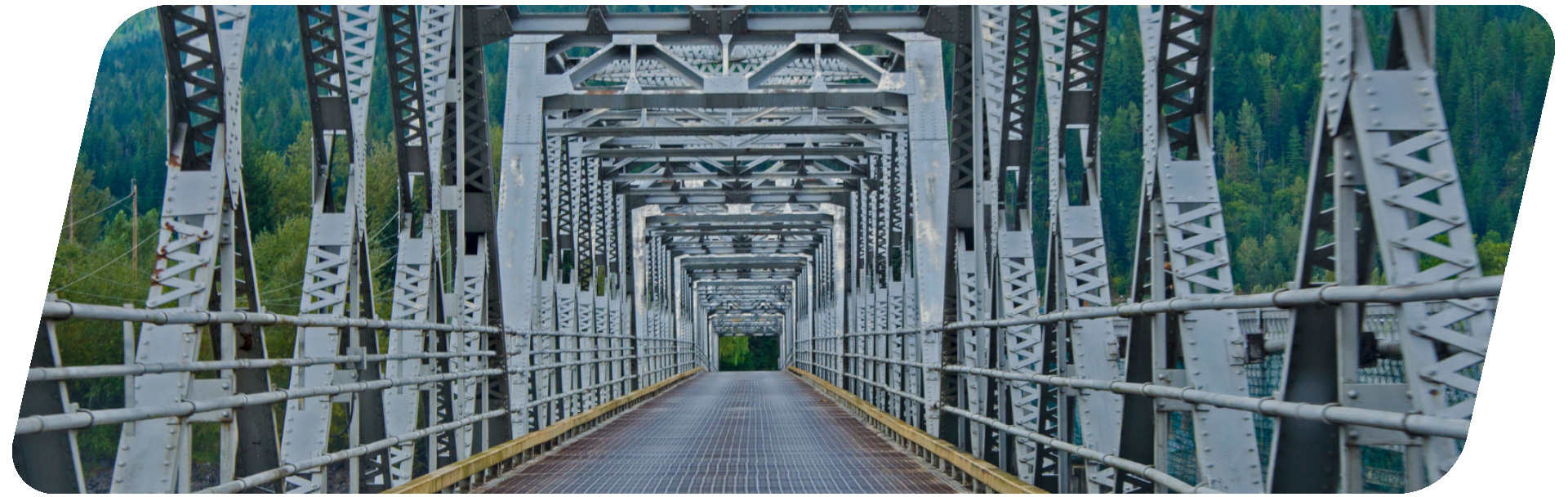

S355J2+N is commonly used for load-bearing structures such as bridges, buildings, and steel frameworks.

Use of S355J2+N in Mechanical Engineering

Thanks to its weldability, this steel is suitable for use in mechanical engineering, locksmithing, and metal construction.

Applications in steel construction and bridge construction.

S355J2+N is ideal for bridge and large steel constructions due to its excellent mechanical properties. For bridge construction, plates according to the railway standard DBS 918002-02 S355J2+N are often used. The standard requires additional tests such as ultrasonic testing (S3/E4) and plate-by-plate inspection at the factory.

Standards and Certifications for S355J2+N

S355J2+N is an unalloyed structural steel that complies with the European standard EN 10025-2. It meets high-quality requirements and can be supplied with certifications such as 3.1 or 3.2 according to EN 10204, depending on the application.

Standards and Certifications for S355J2+N

S355J2+N complies with the European standard EN 10025-2, which defines the technical requirements for unalloyed structural steels.

Test Certificates and Quality Standards for S355J2+N

3.1 Certificate: Material testing by the manufacturer

3.2 Certificate: Independent testing by external inspection bodies such as TÜV, DNV, LR, and others.

Processing and Weldability of S355J2+N

Welding processes and their effects on the material structure

S355J2+N is weldable and can be processed using common methods such as MIG/MAG, TIG, and electrode welding.

Cutting and machining of S355J2+N

The steel can be easily milled, drilled, and cut, with laser and plasma cutting providing particularly precise results. We are happy to cut the steel for you.

Corrosion protection and surface treatments

S355J2+N can be protected from corrosion by galvanizing or painting

Your contact for wear-resistant steel

If you have any questions about our range or services, please feel free to contact our representative. We are happy to assist you.

Heiner Büsselmann

Tel.: +49 (0)421 / 48 40 1922 – 21

E-Mail: hbuesselmann@unionstahl.com

Frequently Asked Questions and Answers

Is S355J2+N stainless?

No, this steel is not stainless, but it can be protected by coatings.

What are the alternatives to S355J2+N?

lternatives include S355J2C+N, S355K2+N, or higher-strength steels like S460.

Can S355J2+N be combined with other steel grades?

Yes, it can be welded or bolted with other construction steels.

What is the temperature resistance of S355J2+N?

S355J2+N retains its strength even at low temperatures down to -20°C.

Is S355J2+N available in galvanized form?

Yes, S355J2+N can be delivered either shot-blasted or shot-blasted and primed.